Product details

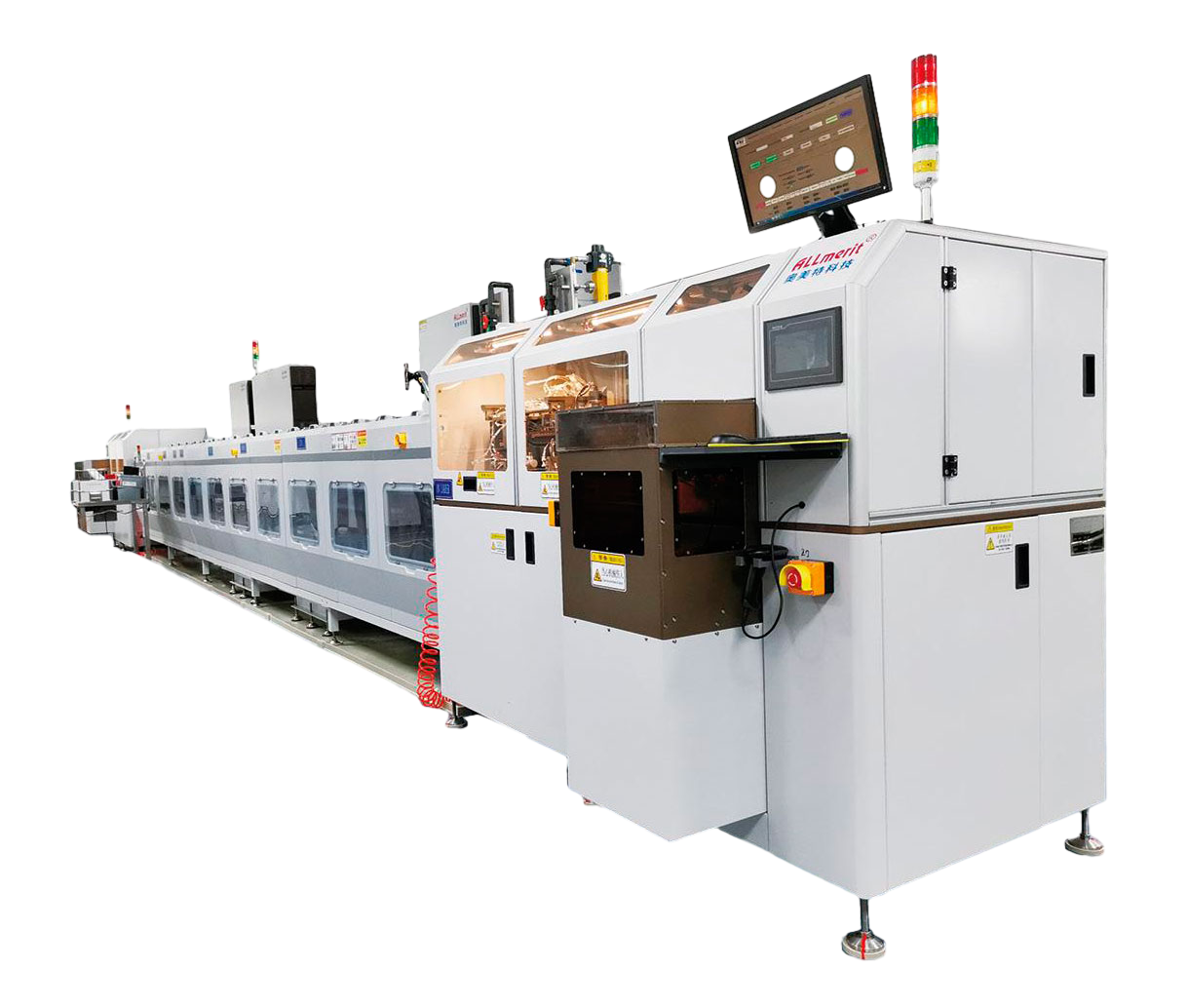

Fully automatic roll-to-roll wide row high-density lead frame wheel plating type selective silver plating equipment

Category:

Product Center

Lead frame silver plating equipment series

Contact us

Product description

Fully automatic roll-to-roll wide row high-density lead frame wheel plating type selective silver plating equipment

It is jointly developed by our company and a famous Japanese lead frame manufacturing company. It is aimed at the problems of current multi-row (100mm) high-density IC, SOT, QFP and other lead frames in traditional production lines, such as low yield and poor thickness uniformity. Comprehensive technical upgrades.

Applicable product sheet width: 10-120mm; sheet thickness: 0.08-1.0mm;

Filming speed is 3-10m; plating area accuracy: ±0.075mm; specifications: 2 channels.

Equipment advantages

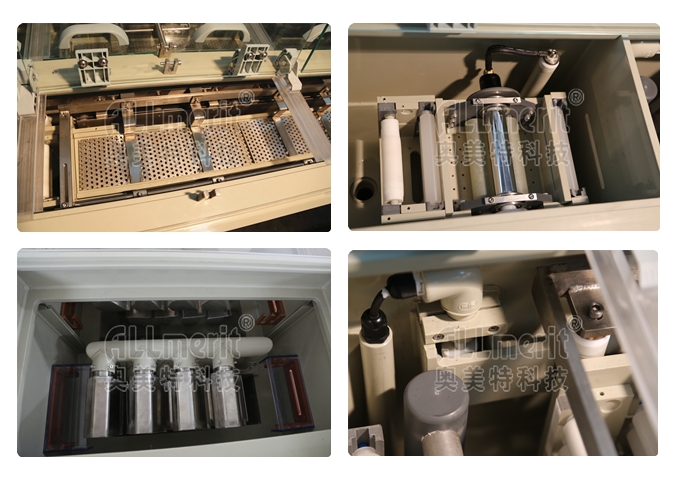

●Host machine: Specially designed for wide-row products, the strength of various shafts and structural parts is more than three times stronger than before, the dual-station consistency accuracy is high, the mold is easy to install, and there is no deviation or misalignment caused by human factors. The mold adopts multi-point limiters to ensure high-precision plating area.

●Efficient conductive device: mercury electrodes are used for conduction in the copper and silver plating tanks, and the conductive rods and anti-scratch rubber rollers rotate synchronously with gears, which will not cause product scratches, and the design does not require any modification when replacing different products. Adjustment can be used directly with different material widths, and the angle can be adjusted as a whole to ensure linear stability of special products.

●Dual current control is used for stripping: the upper and lower and left and right are separated, and supplemented by a special shielding device. It is especially suitable for stripping of wide-row products to ensure that the thickness of the silver layer after stripping is consistent.

●All transmission parts are equipped with bearings, which reduces the resistance of the product inside the equipment and increases the water cutting function. All fixed structures are standard fixed in the grooves to ensure consistent linear height when the product is filmed and reduce the amount of medicine brought out. , significantly reduce production costs

●Drying oven and blower: adopt special design to ensure that the rotation of the wind will not interfere with each other, and adopt low-noise design. High-efficiency heat reflow device significantly reduces energy consumption.

●The discharge buffer adopts high-precision linear guide rails to ensure that the buffer wheel moves up and down smoothly and the product has good linearity. The gravity adjustment buffer is added to ensure consistent tension in the tank and control the uniform speed of discharge. The buffer design adopts multi-level tension control to ensure the linearity of the product in the middle, and the fixed guide wheel can adjust the angle.

This equipment has obtained multiple national patents, and any imitation will be investigated!

Innovative design

●Allmerit equipment products are designed by an international R&D team and adopt a number of independently developed patented technologies.

●Systematic management of R&D design projects, using visual 3D design software to design, what you see is what you get, shortening the design cycle and avoiding design data errors.

Processing details

Use fine workmanship to show reasonable and innovative design.

Equipment materials

Allmerit firmly believes that only by using reliable raw materials and components can equipment with stable and reliable performance be manufactured.

service

Take advantage of our years of expertise to make your project profitable.

●The professional service team is composed of experienced mechanical engineers, technicians, electrical engineers, and electrochemical engineers.

●National one-hour response mechanism for equipment emergency issues.

●Free logistics services are provided. We are responsible for the packaging, loading and unloading of the equipment, and there is zero risk during transportation.

Allmerit strength

Allmerit Focus and continuous investment are just to become a solid backing for your career development!

Related products