Product details

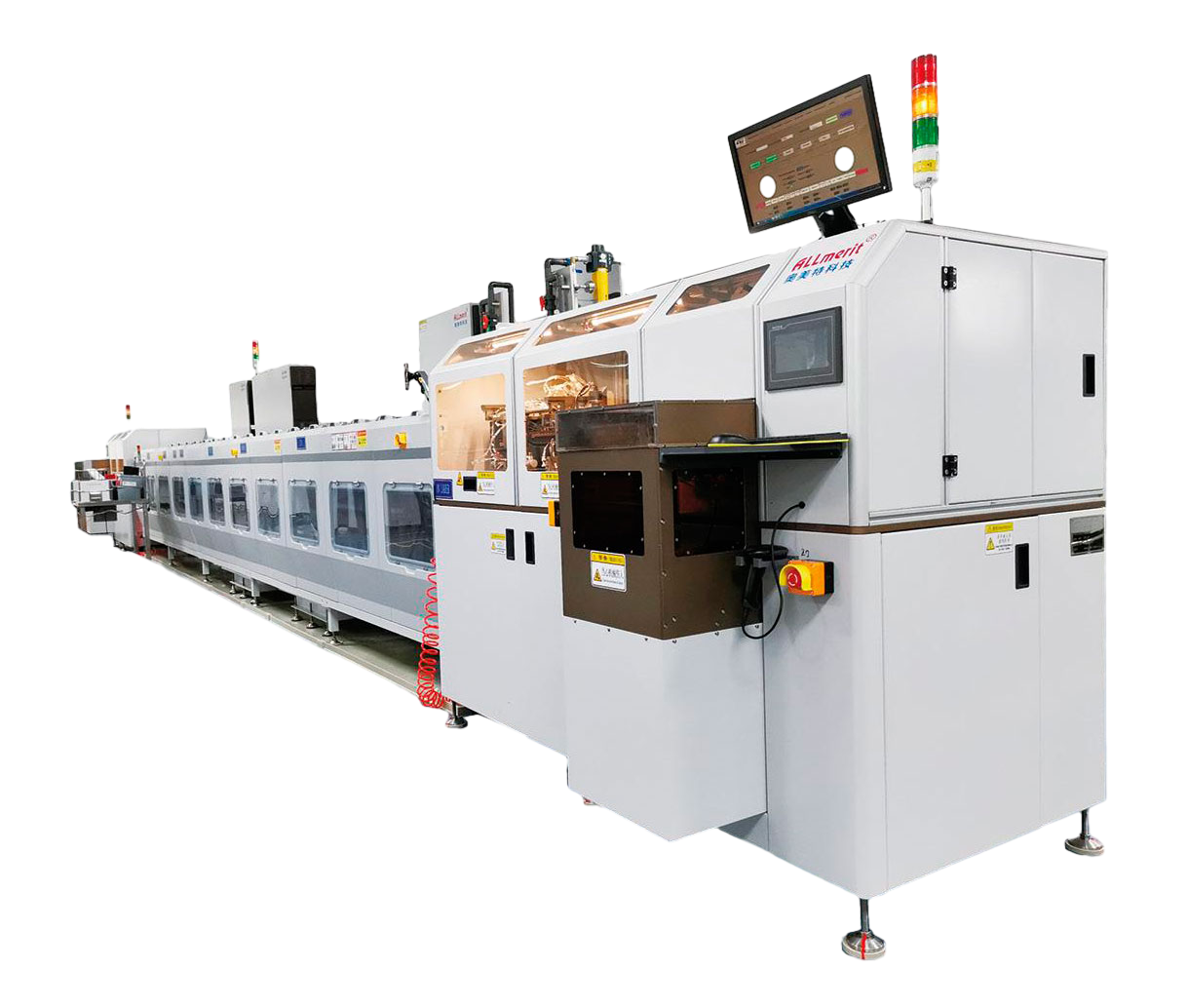

Chip lead frame electrofilm development and silver plating equipment

Category:

Product Center

Lead frame silver plating equipment series

Contact us

Product description

Chip lead frame electrofilm development and silver plating equipment

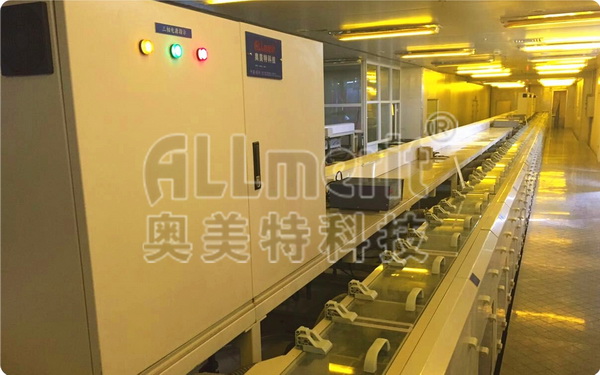

This equipment is designed for special QFN or IC ultra-dense and ultra-fine electroplating areas that cannot be achieved with traditional electroplating molds. It is a specially developed special electroplating equipment that transfers sheet products through steel belts for electrofilming, exposure, development and other processes to electroplating areas. and size are locked, and then silver plating and post-processing are performed to achieve ultra-precise selective plating.

Equipment advantages

●It can realize small plating areas and high-density products that are difficult to achieve with plating mold methods.

●The equipment adopts an adjustable shielding device, which can adapt to products of different widths and ensure the uniformity of product thickness.

●This equipment all uses PLC to control the rectifier output, which can automatically adjust the current according to the number of products to ensure consistent product thickness.

●The equipment can automatically store product parameters, and parameters can be directly retrieved when replacing products, including current, equipment operating speed, etc., which facilitates operators to quickly replace products and ensures that parameters are not adjusted at will.

●Sensors are configured inside the equipment to automatically monitor the operation of the product in the tank, automatically identify the material dropout, and analyze the fault location.

●The equipment is equipped with anti-collision and anti-jamming devices. Some products with poor incoming material conditions can be checked out in time after the equipment passes through to prevent subsequent material jamming.

This equipment has obtained multiple national patents, and any imitation will be investigated!

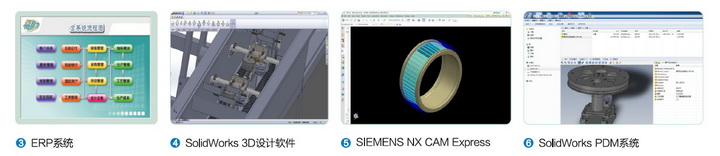

Innovative design

●Allmerit equipment products are designed by an international R&D team and adopt a number of independently developed patented technologies.

●Systematic management of R&D design projects, using visual 3D design software to design, what you see is what you get, shortening the design cycle and avoiding design data errors.

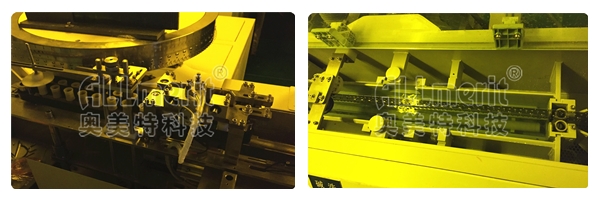

Processing details

Use fine workmanship to show reasonable and innovative design.

Equipment materials

Allmerit firmly believes that only by using reliable raw materials and components can equipment with stable and reliable performance be manufactured.

service

Take advantage of our years of expertise to make your project profitable.

●The professional service team is composed of experienced mechanical engineers, technicians, electrical engineers, and electrochemical engineers.

●National one-hour response mechanism for equipment emergency issues.

●Free logistics services are provided. We are responsible for the packaging, loading and unloading of the equipment, and there is zero risk during transportation.

Allmerit strength

Allmerit Focus and continuous investment are just to become a solid backing for your career development!

Related products