News

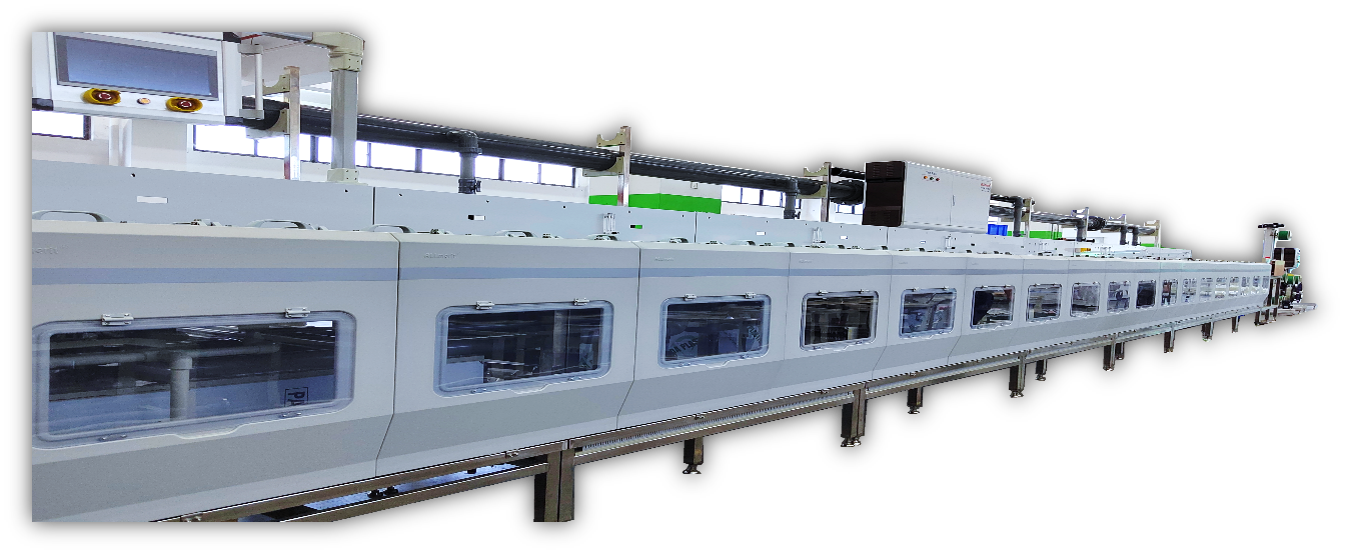

The pursuit of excellence, cast a classic! Allmerit technology nickel palladium silver gold continuous plating production equipment cast excellent quality new height!

Release time:

2024-09-21 17:30

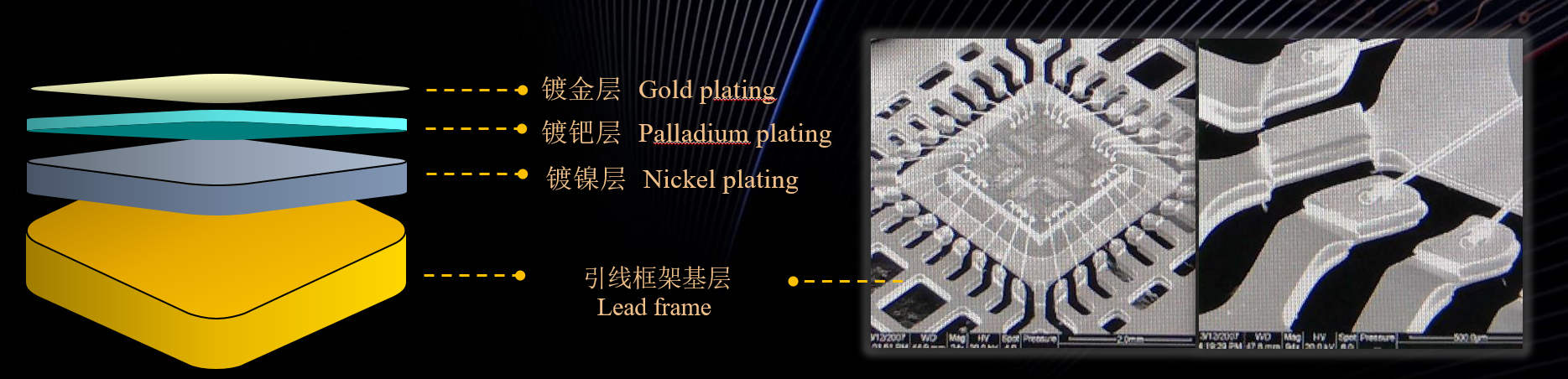

Electroplating of nickel palladium gold (ENEPIG) is a surface treatment technology widely used in the semiconductor industry. Its main processes include degreasing, microetching, prepreg, activation, nickel precipitation, palladium precipitation, gold precipitation and drying. These steps deposit nickel, palladium and gold layer by layer on the metal substrate by chemical reaction, forming a strong and corrosion-resistant surface coating.

Allmerit Technology has been deeply involved in the field of semiconductor electrochemical equipment for more than 20 years, and has already firmly mastered this equipment technology. Its mature technology and rich production experience are the greatest guarantee for customers to design and produce such equipment by Allmerit.

This equipment is mainly aimed at electroplating nickel palladium gold on copper alloy and iron alloy electroplating substrates. The lead frame after nickel palladium gold plating has excellent corrosion resistance, good bonding ability and tensile strength. It also improves the weldability, is suitable for lead-free reflow soldering, can withstand multiple lead-free reflow soldering cycles, and at the same time, the frame product is resistant to high temperature aging and has high stability.

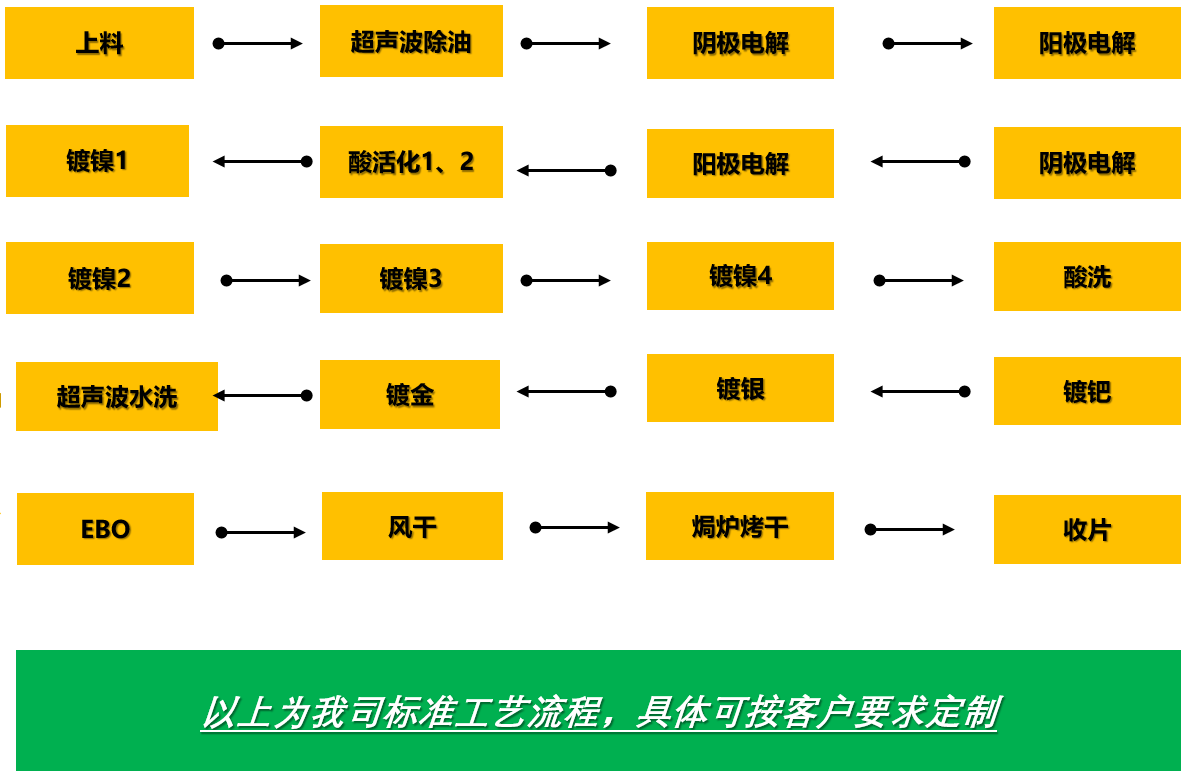

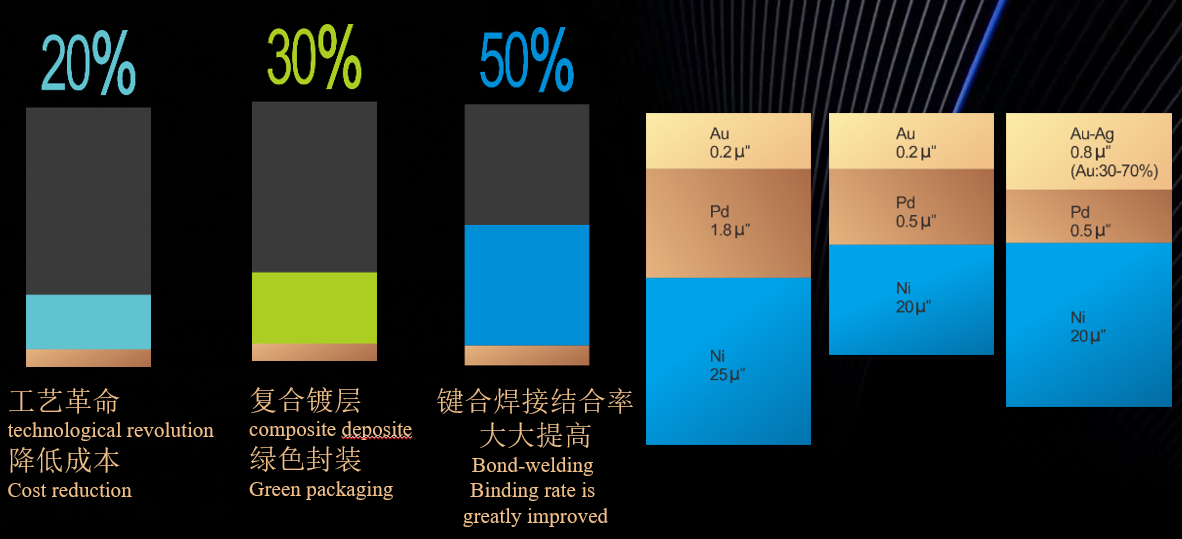

In addition, Allmerit has made a new design modification from this equipment, which can electroplate nickel palladium silver gold on the lead frame, and add silver plating process to generate silver gold alloy. The silver layer not only provides excellent electrical conductivity and thermal conductivity, which is convenient for customers to wire, but also saves production costs. The specific process flow is as follows:

In addition to its own characteristics of the nickel-plated palladium process itself, Allmerit also gives it more advantages when designing the equipment:

1. One-time electroplating is completed, without local silver plating and tin plating after plastic sealing;

2. No whisker occurs, suitable for products with high reliability requirements;

3, anti-silver paste diffusion (EBO) is easy to achieve;

4. The ductility of the frame is strengthened, and the cutting is not easy to deform;

5, the use of nickel roughening process to improve the adhesion of plastic packaging materials; has excellent bonding and welding performance;

6. Highly stable receiving and discharging mode is more suitable for high-end QFN products with weak structure and easy deformation.

The lead frame electroplated by Allmerit's nickel-palladium-silver-gold continuous electroplating production equipment has uniform coating thickness, thickness distribution CPK ≥ 1.67, consistency and high quality of coating in various regions, and unparalleled adhesion and significant tensile strength of the lead frame. For customers, this means that in the subsequent manufacturing process, they can enjoy more stable and reliable process performance, as well as the high quality guarantee of the final product, so as to help customers stand out in the market competition.

Relevant news