News

Allmerit's newly launched Class 1 reliability power module and multi-pin LQFP high-speed tin-plating equipment breaks the technological monopoly of Europe, Japan, and South Korea, realizing the replacement of domestic equipment!

Release time:

2025-06-21 17:30

For many years, European and Japanese and South Korean companies have monopolized tin-plating technology for high-power modules and multi-pin products in China. As a leader in the semiconductor plating and etching equipment sector, Allmerit has been constantly striving for technological advancements and exploring new development opportunities.

In recent years, Allmerit, leveraging its deep technological accumulation and relentless exploration, has made significant progress in semiconductor lead frame tin plating technology. Through collaboration with globally renowned semiconductor manufacturers, it has successfully achieved domestic equipment substitution, accelerating the localization of new energy semiconductor equipment.

Allmerit's recently launched high-speed tin-plating equipment for Tier 1 reliability power modules uses a fully automated operation mode. It automatically adjusts various components via servo motors, enabling automatic switching between various types of Tier 1 reliability power modules. It offers broad product size compatibility, with width compatibility of 60mm-100mm and length compatibility of 100mm-300mm.

After post-processing such as softening, high-pressure water overflow removal, and tin plating, the appearance is normal, the plating layer crystals are fine, the plating thickness is normal, CPK is greater than 2.0, fully meeting quality requirements.

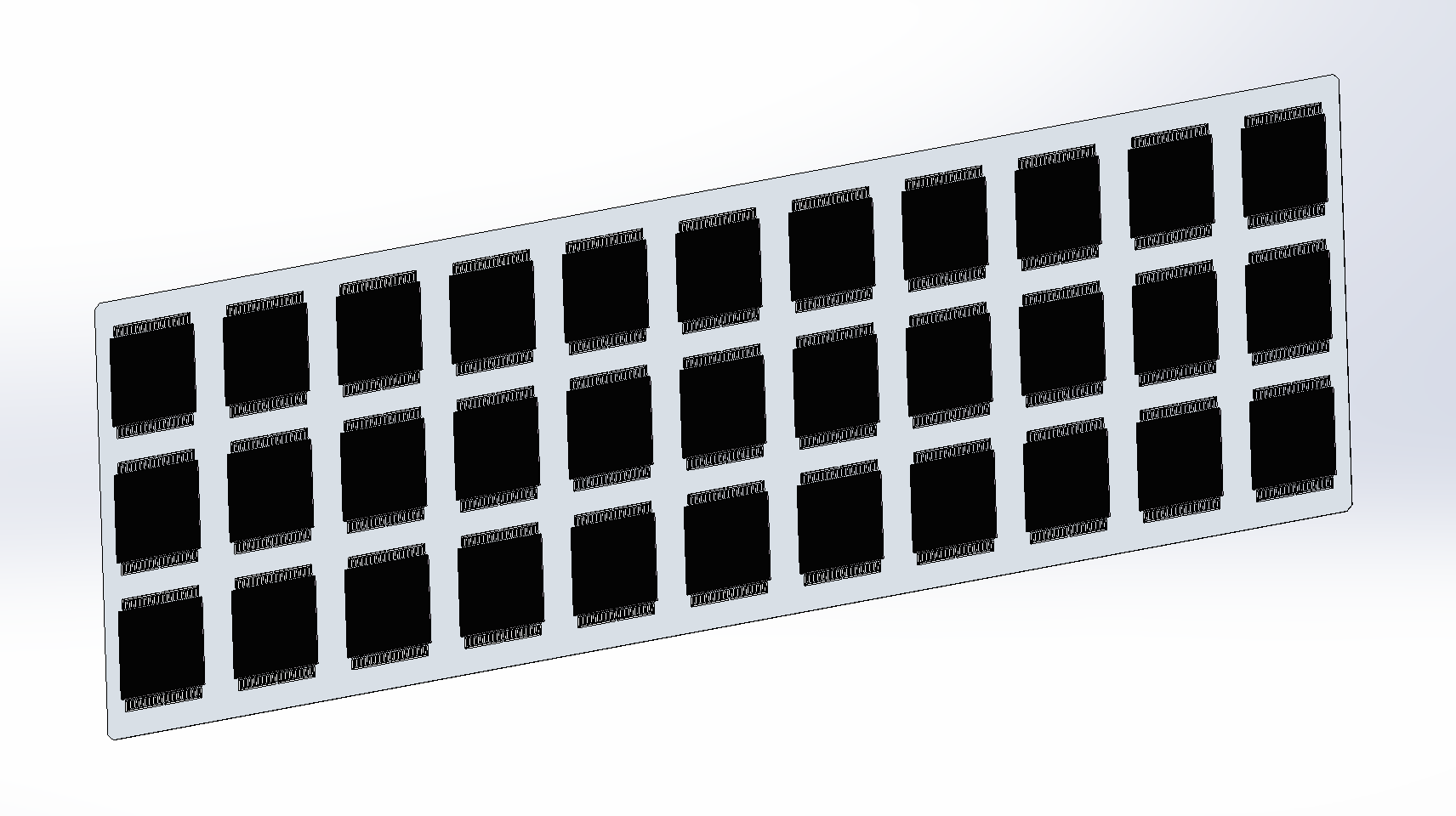

In addition, Allmerit has launched a fully automatic high-speed tin-plating equipment for multi-pin LQFP products. Targeting the electroplating of multi-pin LQFP products, the product can accommodate up to 144 pins, with size compatibility of width: 60mm---100mm, length: 200mm---300mm. It achieves a tin plating CPK of over 2.1 while ensuring coplanarity and eliminating whisker formation.

Through the left and right movement of the cylinder/motor, it can switch between two different types of feeders (slot magazine aluminum alloy side-pushing feeder + stack magazine), adapting to different product conditions. Through servo module/cylinder/motor adjustment and control, the loading and unloading clamping mechanism independently grasps the wafers, reducing labor costs and achieving fully automated loading and unloading.

These two pieces of equipment innovatively utilize a U-shaped design concept. This unique design not only optimizes the production process but also significantly saves customers' factory floor space, maximizing space utilization efficiency.

It is particularly noteworthy that both pieces of equipment have highly integrated functional characteristics. They can achieve integrated operation of online softening treatment, precise high-pressure water overflow removal, and tin plating after molding, significantly improving the continuity and efficiency of the production process, greatly enhancing production efficiency and product quality.

More than halfway through 2025, Allmerit, with its outstanding innovation capabilities and relentless pursuit of technology, has won the favor of numerous semiconductor companies, with frequent shipments. It has achieved significant innovation and breakthroughs in the field of semiconductor lead frame plating and etching equipment technology.

Currently, Allmerit's newly upgraded high-speed tin-plating equipment for Tier 1 reliability power modules and fully automatic high-speed tin-plating equipment for multi-pin LQFP products have been put into mass production. They are helping semiconductor companies at the forefront of the automotive integrated circuit field significantly improve production efficiency and product yield, creating greater value for them.

Prev

Relevant news