News

Innovate and improve! Allmerit is fully driving the R&D engine, dedicated to pursuing innovation in integrated circuit lead frame plating equipment!

Release time:

2024-11-16 17:30

In the rapidly changing business environment, innovation has become a key factor in driving sustainable development and maintaining competitiveness for enterprises. The semiconductor industry, as a cutting-edge technology sector, places even greater emphasis on the iteration and updating of technology.

Allmerit encourages employees to boldly try new ideas, technologies, and methods, constantly challenging tradition and breaking through themselves. The company has also established a comprehensive innovation incentive mechanism, providing generous rewards and honors to individuals and teams that achieve outstanding results in innovation.

Driven by these mechanisms, the passion for R&D innovation within the company burns like a raging fire, leading to the iteration and updating of integrated circuit lead frame plating equipment and technology. We continuously break through ourselves, pursue excellence, and strive to refine every detail to achieve high product quality.

Through continuous investment in R&D and technological innovation, Allmerit's integrated circuit high-density lead frame plating equipment has become increasingly diverse, and the performance of the equipment has significantly improved. From precision molds to high-precision integrated circuit lead frame plating equipment, each product embodies our wisdom and hard work, showcasing our persistent pursuit of quality.

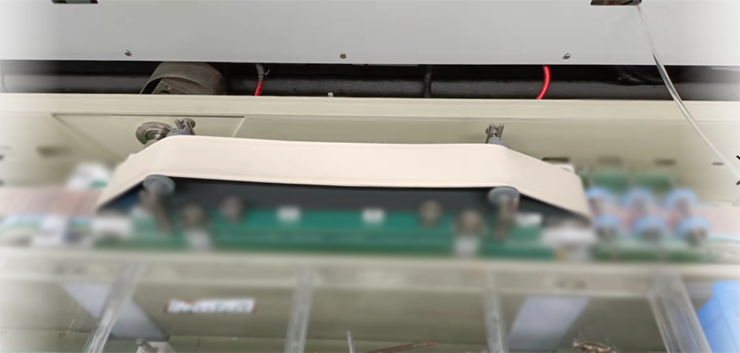

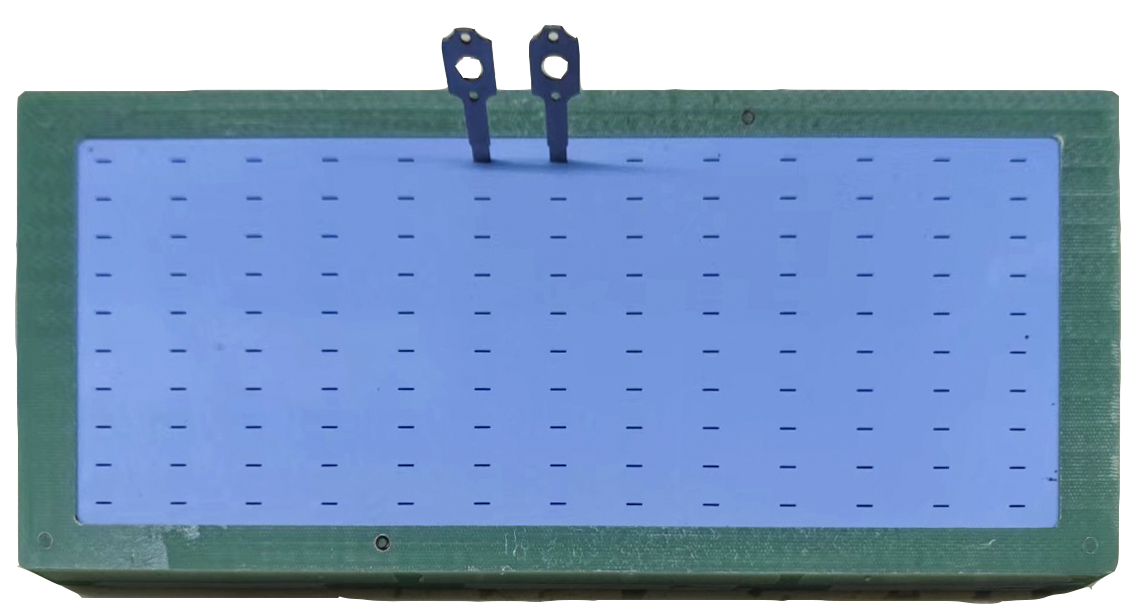

Tank chain mold mask belt

The core of Allmerit's integrated circuit lead frame tank chain selective plating equipment lies in the tank chain plating mold that controls the plating area in the silver plating section. The tank chain mold mask belt is an important accessory that works in conjunction with the tank chain mold, allowing for the production of high-density, high-footprint lead frames with complex plating area structures and larger product pitches, such as LQFP, QFP, TQFP, SSOP, TSSOP, SOT, SOM, DIP, and PDIP.

From purchased installation to independent R&D production, this custom mask belt designed for integrated circuit lead frame tank chain selective plating equipment not only significantly improves quality but also enhances compatibility, effectively increasing the plating yield of the equipment.

The tank chain mask belt consists of two parts: the substrate and the surface material. The substrate is made of high-temperature and acid-alkali resistant elastic material, while the surface material is made of imported silicone, which is high-temperature resistant, acid-alkali resistant, and wear-resistant, capable of stable operation under conditions of -60° to 250°, improving production efficiency and product yield.

Currently, the tank chain mask belt mainly comes in three specifications: 1600mmX75mmX10mm, 1600mmX85mmX10mm, and 1600mmX95mmX10mm, with hardness adjustable according to different customer product requirements.

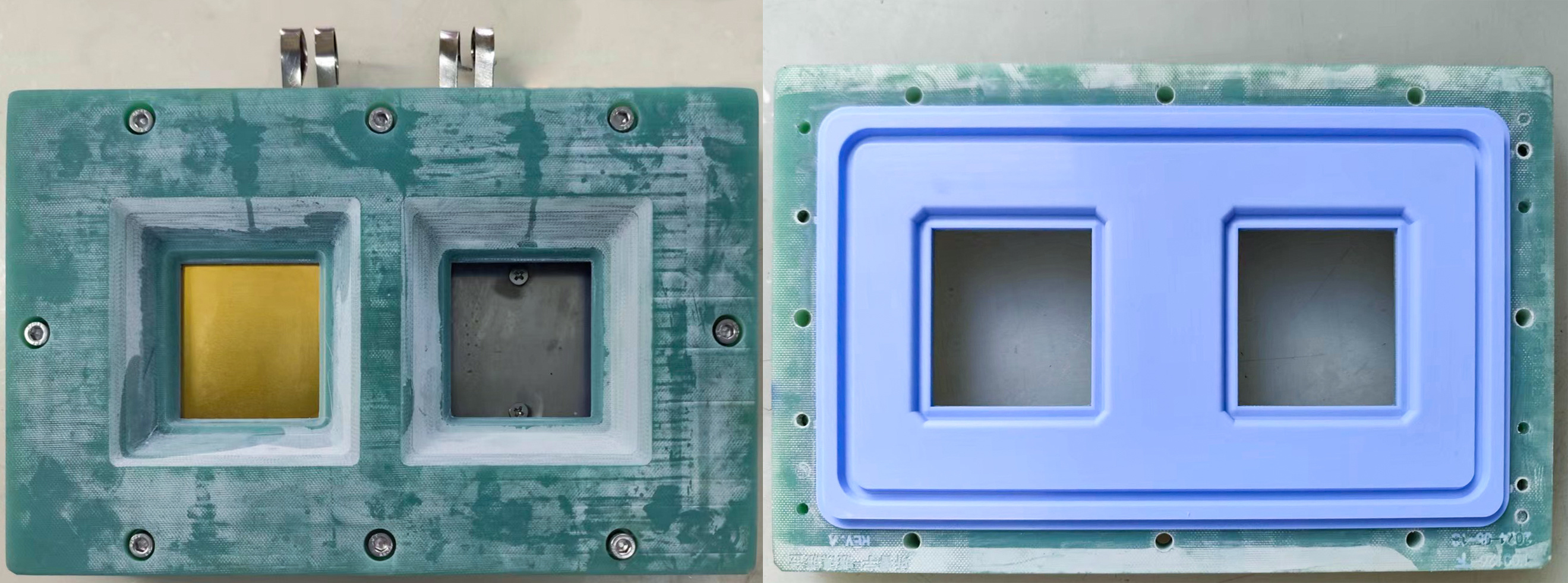

Hanging plating mold

This plating mold adopts a hanging plating mode, achieving the effect of double-sided plating on the lead frame, ensuring that the plating layer is uniform on both sides of the lead frame. According to Allmerit's specially designed structure, the sealing of the plating mold surface adhesive is guaranteed, which can effectively control the plating dimensions.

It is not limited to flat plating; it can also plate some irregular products, making it more versatile compared to general pressure plate molds. It is mainly compatible with tin, nickel, and gold plating equipment.

Selective de-tinning mold

This set of fixtures has high processing difficulty for aluminum molds and requires high sealing performance, but this de-plating mold can accommodate thinner materials and can de-plate a large number of materials simultaneously, with a fast de-plating speed.

Allmerit has never stopped pursuing extreme precision in molds. In the field of R&D design, it always adheres to the spirit of innovation, striving to elevate mold precision to new heights; in the production manufacturing process, it upholds rigorous and meticulous production standards, ensuring that every product perfectly aligns with the design concept. This allows Allmerit's integrated circuit lead frame plating equipment and Allmerit molds to be more compatible, working together to create higher quality plating effects and support the new development of the semiconductor industry.

Relevant news