Product details

All categories

Plastic lead frame high-speed tin plating equipment series

According to customer requirements, the following equipment can be customized:

Customize processes according to product characteristics;

The SECS-GEM protocol can be built-in to facilitate access to the customer's production management system;

The maintenance reminder function can be configured to make equipment maintenance smarter;

Category:

Lead frame tin plating equipment series

Key words:

Contact us

Product description

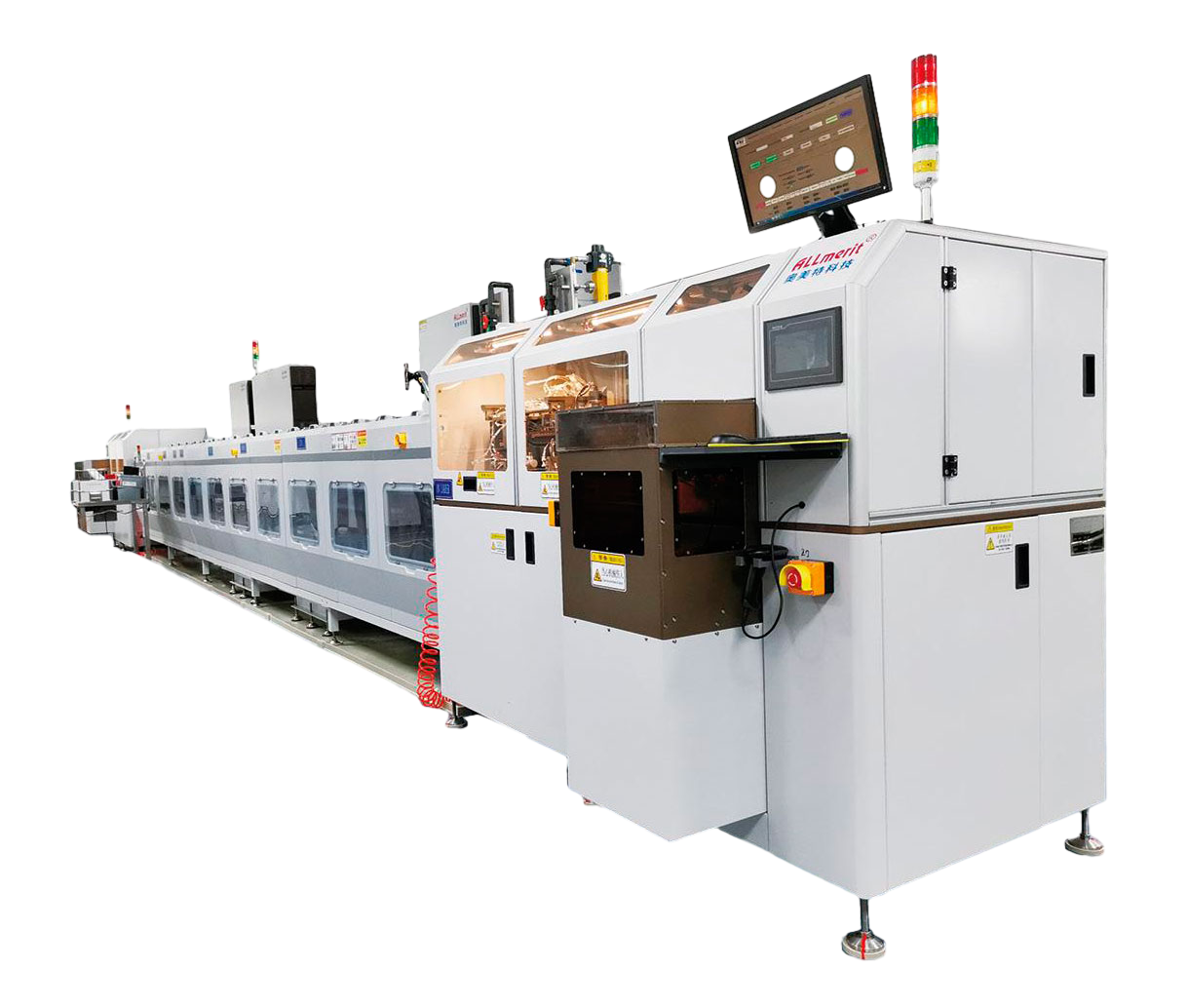

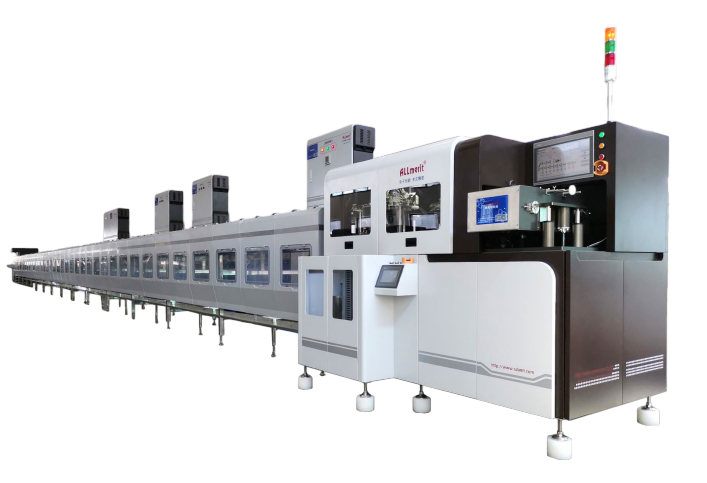

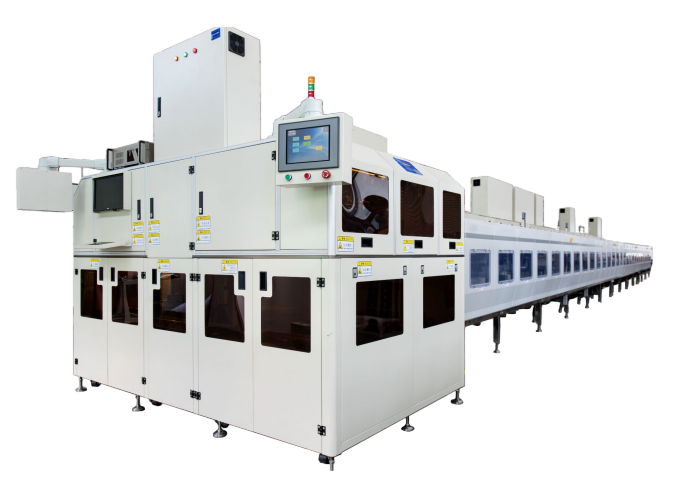

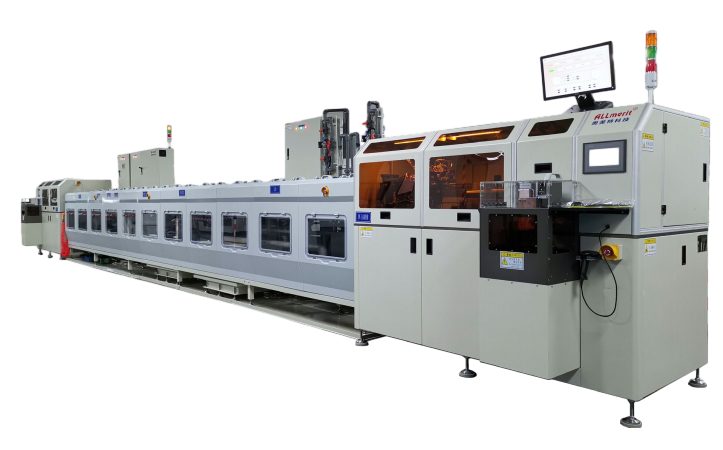

Auto high-speed Sn plating equipment

Equipment performance parameters

Equipment layout optional: linear, U-shaped, circular

Optional feeding mechanism: fully automatic, semi-automatic feeding, manual feeding

Applicable Products:

Width: 30-110 mm;

Lead frame substrate thickness: 0.15-1.0 mm;

Plastic body thickness: 1.0-10 mm

Filming speed: 3-12 meters/minute (based on product);

Tin plating thickness: 4-15 microns;

Specifications: 1-2 channels

According to customer requirements, the following equipment can be customized:

Customize processes according to product characteristics;

The SECS-GEM protocol can be built-in to facilitate access to the customer's production management system;

The maintenance reminder function can be configured to make equipment maintenance smarter;

…

For automotive-grade plastic-encapsulated lead frame modules, it has passed the plastic-sealed Level 1 reliability test (automotive grade).

In order to meet the requirements of harsh automotive applications, the tin plating thickness CPK>1.67.

Optional feeding mechanism: fully automatic, semi-automatic feeding, manual feeding

Applicable Products:

Width: 30-110 mm;

Lead frame substrate thickness: 0.15-1.0 mm;

Plastic body thickness: 1.0-10 mm

Filming speed: 3-12 meters/minute (based on product);

Tin plating thickness: 4-15 microns;

Specifications: 1-2 channels

According to customer requirements, the following equipment can be customized:

Customize processes according to product characteristics;

The SECS-GEM protocol can be built-in to facilitate access to the customer's production management system;

The maintenance reminder function can be configured to make equipment maintenance smarter;

…

For automotive-grade plastic-encapsulated lead frame modules, it has passed the plastic-sealed Level 1 reliability test (automotive grade).

In order to meet the requirements of harsh automotive applications, the tin plating thickness CPK>1.67.

Ogilvy Plastic Lead Frame High Speed Tin Plating Feeding Mechanism Selection Instructions

Manual loading mechanism

Features: The equipment is cost-effective and the equipment investment is small; the feeding operation is simple, the maintenance is simple, and the requirements for machine operators and maintenance personnel are low.

It is easy to switch between different products for tin plating production, and is more suitable for electroplating OEM companies and packaging companies that have requirements for cost-effective equipment.

Features: The equipment is cost-effective and the equipment investment is small; the feeding operation is simple, the maintenance is simple, and the requirements for machine operators and maintenance personnel are low.

It is easy to switch between different products for tin plating production, and is more suitable for electroplating OEM companies and packaging companies that have requirements for cost-effective equipment.

Semi-automatic cutting and feeding mechanism

Features: The loading operation is simple, and the requirements for machine operators are not high; the equipment is cost-effective and can switch to a variety of products for production;

It is suitable for packaging companies and electroplating OEM companies that have certain requirements for equipment automation.

It is suitable for packaging companies and electroplating OEM companies that have certain requirements for equipment automation.

Fully automatic thread cutting and feeding mechanism (manual feeding can be switched)

Features: The equipment has a high degree of automation; the loading operation is convenient, and it is suitable for the tin plating production of large-volume products;

The equipment control software is powerful and can store the production parameters of different products and switch product production with one click;

Using Ogilvy's unique patent, the manual feeding system can be switched immediately to adapt to the increased product production in the short term;

Suitable for packaging companies and electroplating OEM companies that carry out large-scale mass production.

The equipment control software is powerful and can store the production parameters of different products and switch product production with one click;

Using Ogilvy's unique patent, the manual feeding system can be switched immediately to adapt to the increased product production in the short term;

Suitable for packaging companies and electroplating OEM companies that carry out large-scale mass production.

Ogilvy plastic lead frame high-speed tin plating equipment - integrated high-pressure flash removal process (customized)

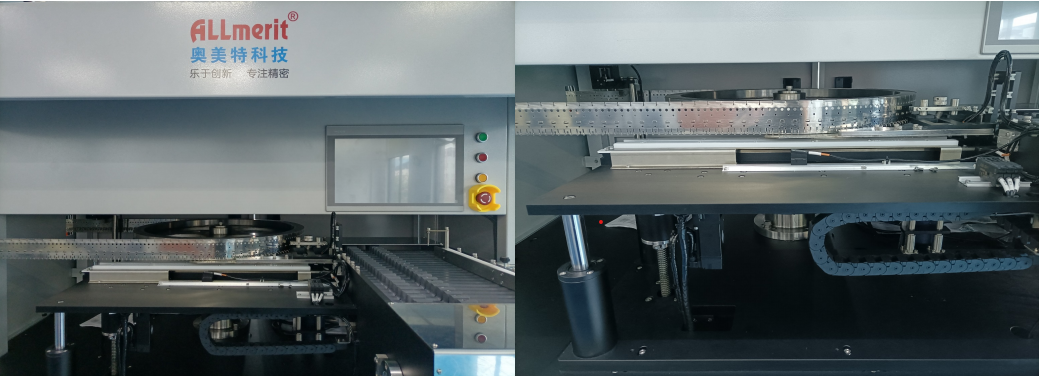

Part of the appearance of Ogilvy plastic lead frame high-speed tin plating equipment

Ogilvy plastic lead frame high-speed tin plating equipment - control software human-machine interface

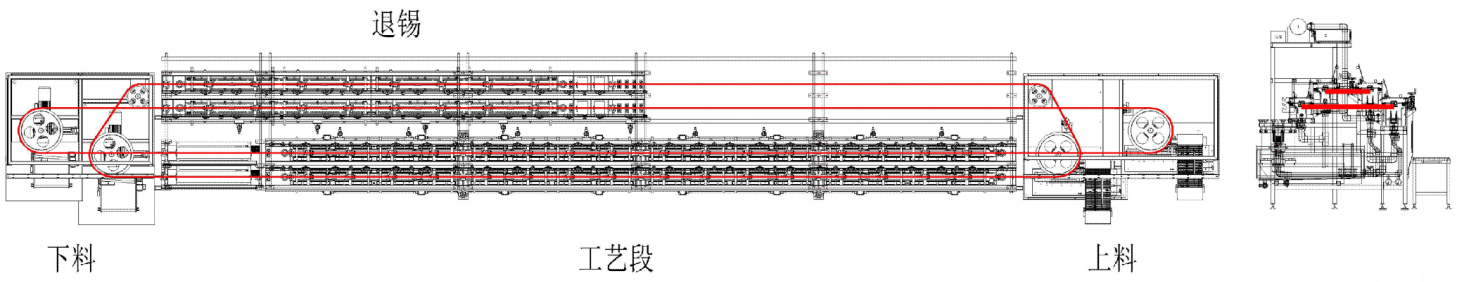

Ogilvy plastic lead frame high-speed tin plating equipment structure selection instructions

Linear tin plating equipment

Features: simple operation and convenient maintenance; long steel strip life and long wire body; low equipment investment and high cost performance.

U-shaped tin plating equipment

Features: The equipment has a short wire body, and the loading and unloading mechanism is on the same side of the equipment, making it easier to watch and manage. The steel strip has a shorter life than the linear type, and the operation and maintenance are more professional.

Ring-type tin plating equipment, features: the equipment line is short, and the unloading mechanism is set in the middle of the equipment (can be flexibly customized according to the site).

Dual channel tin plating equipment

Features: The size of the equipment line is smaller than that of the two pieces of equipment, and it occupies a small area; the equipment operates in dual channels and can produce two products at the same time, or increase the production capacity of a single product.

Next

Related products