News

Allmerit integrated circuit lead frame press plate selective plating equipment and molds

Release time:

2022-07-13 13:42

1. Overview of the development history of selective electroplating technology

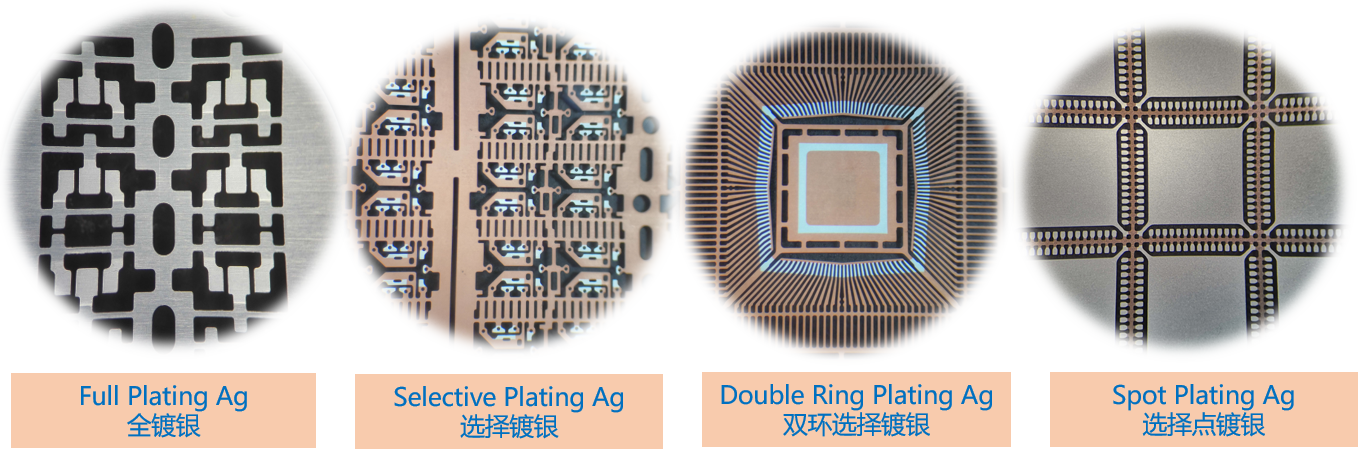

In the early days of the development of IC lead frame plating, products were generally fully gold-plated. However, as the market demand for lead frame production increased, the relative cost was very high, making it difficult for many small and medium-sized companies to accept it. In the early 1970s, some companies began to use full silver plating technology instead of gold plating. In the late 1970s, some Japanese companies began to use partial silver plating, which is our current selective plating. This method can save precious metals. Therefore, it is widely used in the semiconductor material industry, developed rapidly, and continues to this day.

In the early days of the development of selective electroplating, the liquid level control method was mainly used. However, this method has its limitations. It can only be electroplated on one end of products with a specific structure. When there are two ends that do not need electroplating, and only the middle position needs electroplating, it is difficult to do so. . In the later period, as high-speed electroplating technology and processes matured, special masks began to be used to perform electroplating in different areas, that is, selective plating tools (Selective Plating Tool). This method makes the plating position flexible, as long as you want to The mold opening is designed at the position of electroplating to allow the plating solution to be sprayed, so that effective electroplating can be carried out. Pressure plate selective electroplating has gradually developed since then. After more than 30 years of development, selective electroplating technology has been widely used in the IC material industry. At the same time, a number of professional companies have emerged that design, develop and produce corresponding electroplating equipment. The more famous ones include the Swiss company EESA and the Dutch company MECO. In particular, MECO has basically transformed into the solar cell electroplating and environmental protection industry in recent years. This gap in the market has brought unprecedented opportunities to Dongguan Ogilvy Technology. Through more than 20 years of accumulation and technology accumulation, coupled with increasing investment in research and development in recent years, Dongguan Ogilvy Technology has successively launched a series of domestic and foreign fine products. Industry-leading products. Among them, chip type and continuous plate pressing equipment is one of them. The pressure plate mold corresponding to this equipment, like the corresponding equipment, is also ahead of its domestic and foreign counterparts, and gradually widens the gap with it.

Dongguan Allmerit Technology focuses on special wet process equipment for the production of semiconductors and integrated circuits, is committed to the domestic replacement of smart equipment in this industry, and is committed to making our contribution in solving key technologies that stuck.

2. The principle of pressure plate selective plating and the basic structure of the mold

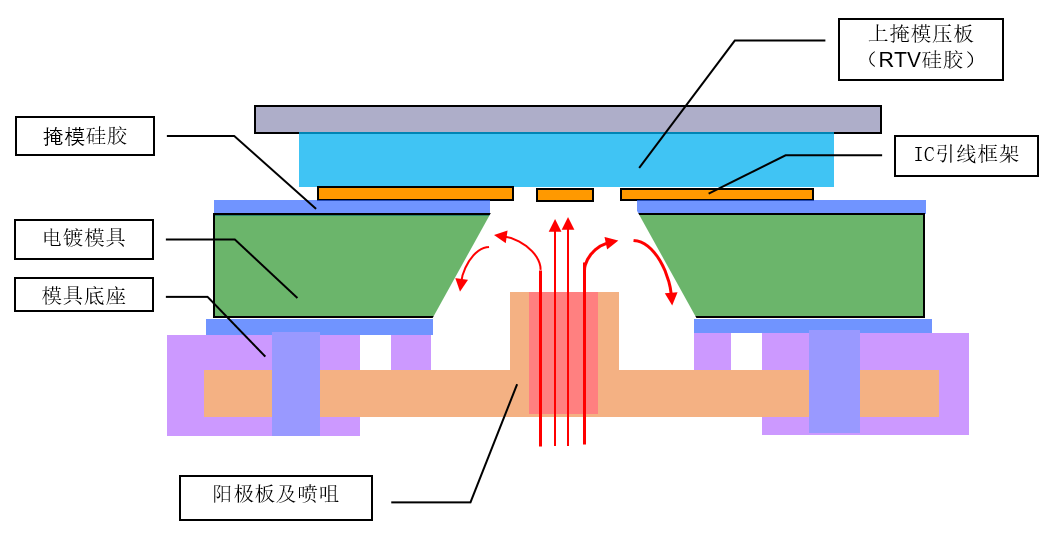

The so-called pressure plate selective plating is what we usually call the flat plate point sputtering method. This kind of electroplating method is to use a silicone rubber structural pressure plate to clamp the lead frame in a mask opening device of a certain length, and the electroplating mold mask opening Install an anode nozzle at a high speed to eject the plating solution at high speed, which can reduce the thickness of the diffusion layer and achieve high-speed electroplating. This method has high precision in the electroplating range, low mold cost, and is widely used. It is not only suitable for continuous electroplating, but also for short-size intermittent independent plate plating. However, its film speed is low, generally 2.0-3.0m/ min., which is more suitable for small and medium-sized batch production, and the device has high flexibility and is easy to debug. The structure of flat plate point spraying method is shown in Figure 1-1:

Figure 1-1 Schematic diagram of pressure plate selective plating composition

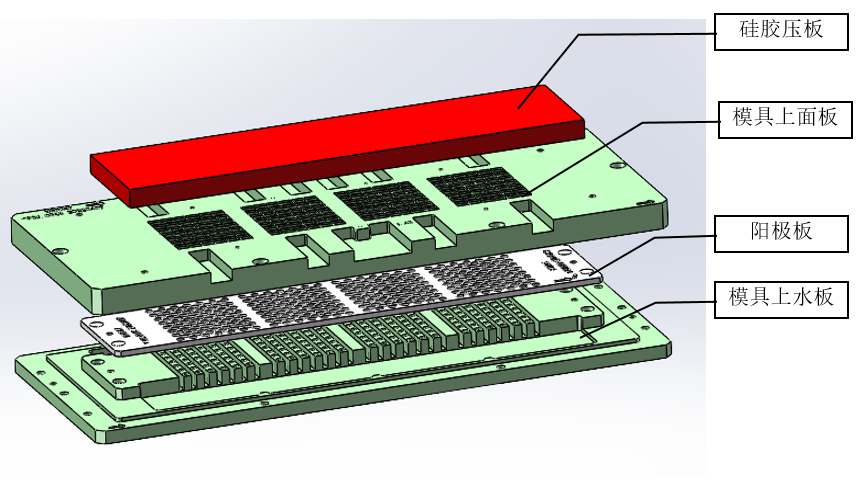

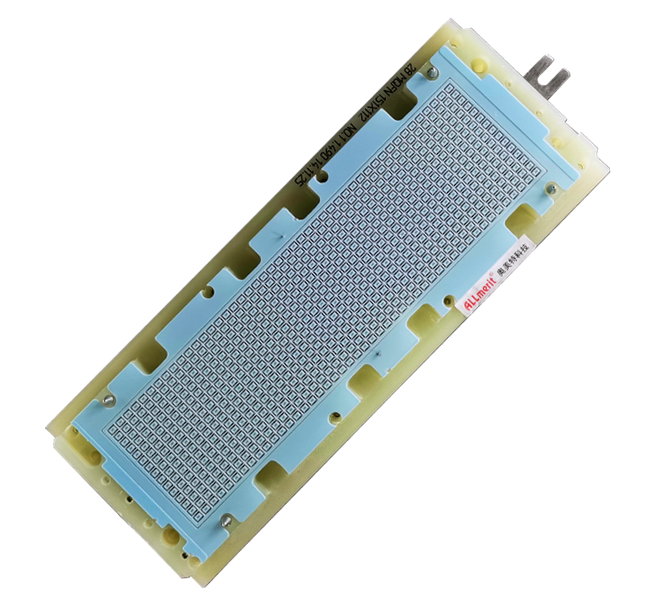

2.1 Basic structure and finished product of platen mold

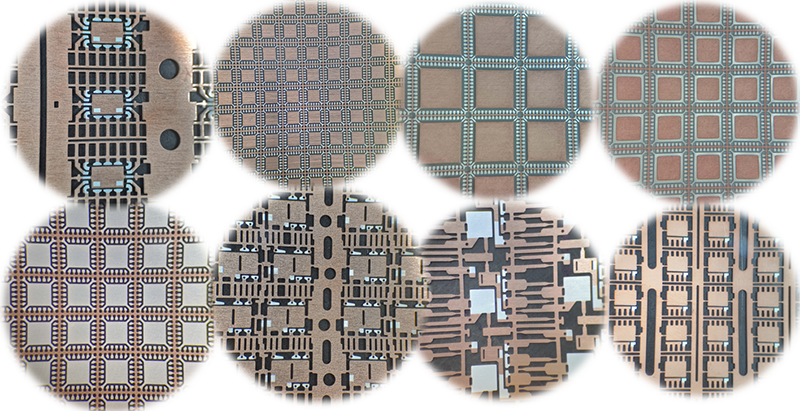

2.2 Products and applications that can be achieved with platen molds

The pressure plate mold can meet the plating requirements of all types and structures of lead frames. It is the most inclusive category of mechanical selection plating, and the accuracy of static plating is much higher than that of dynamic plating, so it is used by lead frame manufacturers in more cases. Used for selective plating of QFN products with weaker product structures and higher density and precision requirements.

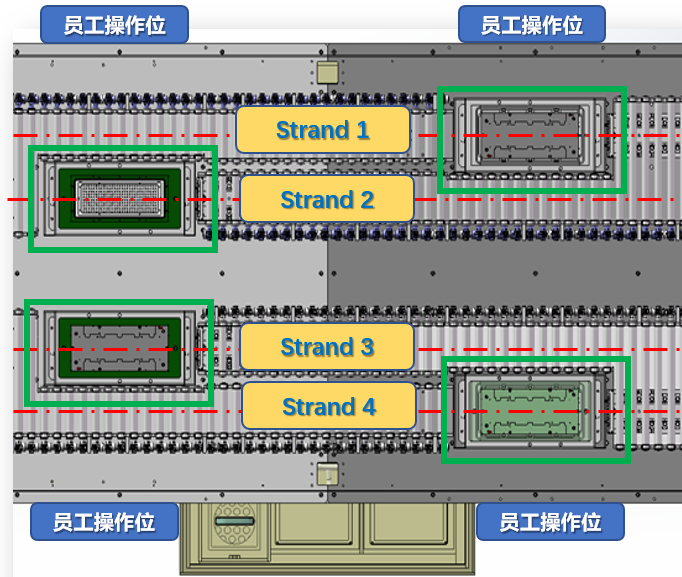

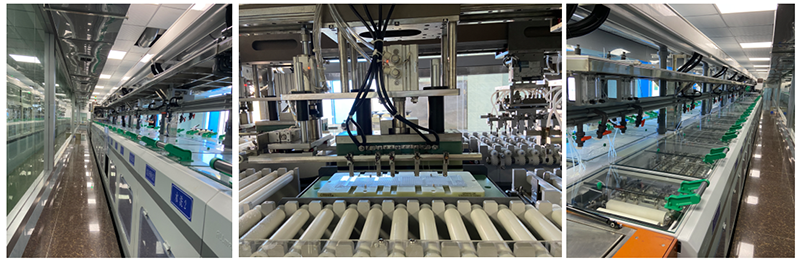

3. Parameters and characteristics of Allmerit chip platen equipment

Allmerit technology platen equipment has four channels, which can be operated separately on the left and right sides. Two lines can be operated on one side. The silver plating part is arranged in a staggered position on one side and does not interfere with each other. The electroplating mold is easy to change and there is no need to stop the lines next to it. The silver plating part adopts the inner cavity reflow mode, which eliminates plating solution splash and steam generation, which can reduce the risk of precious metal splash and leakage, and the operation is safer and more reliable. The silver plating part is equipped with a visual air pressure gauge, and the pressure can be freely adjusted according to different products.

3.1 Basic parameters of equipment

The total length of the equipment is about 34m, the width is 1.8m (excluding the size of the filter barrel), and the height is 2.8m, including the top exhaust pipe, wire trough, etc. Speed: 0.2-2.0m/min, normal production speed 1.0m/min, electroplating tolerance: +/-0.075mm; plated materials and types of chip platen equipment, copper alloy A194, C7025, iron-nickel alloy Alloy 42, etc. ( Etched high-density lead frame), plating product types QFN, DFN (Package Size 2.5x2.5-12x12), Ring, Double Ring Plating, other types of IC products such as SOP, QFP, SOT, DIP, etc.

3.2 Equipment appearance and core technology display

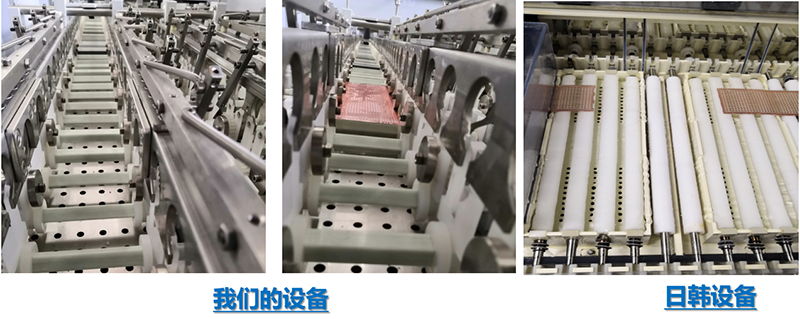

For the first time, Allmerit Technology has solved the technical difficulties and inconvenient operation and adjustment of tunnel-type operation, and avoided problems such as scratches and pollution on the silver-plated surface caused by the roller-type equipment in Japan and South Korea.

Allmerit Technology first developed plate electroplating equipment in China in 2002. Through more than 20 years of technological precipitation and continuous improvement, it also combined with some special requirements of customers, making our equipment structural design more reasonable, functions more reliable, and operation more efficient. Humanize.

In recent years, Allmerit Technology has provided electroplating equipment, selective plating molds and professional after-sales services to many domestic and foreign leading lead frame companies. Our selective mold products are exported to Southeast Asia and Taiwan, China, further helping our cooperation The development and growth of our partners has enabled them to even surpass their Japanese and Korean counterparts in improving their electroplating capabilities, which has greatly improved the competitiveness of customers in the industry. Customers' unanimous recognition and affirmation of our products has also provided a solid foundation for Allmerit Technology's equipment and molds. R&D provides a steady stream of motivation. Allmerit Technology firmly believes that the most reasonable design, the best price, the best quality and the fastest delivery will definitely allow us to create higher value for our customers and help us stand out in the industry.

Next

Relevant news